Project Description

Overview

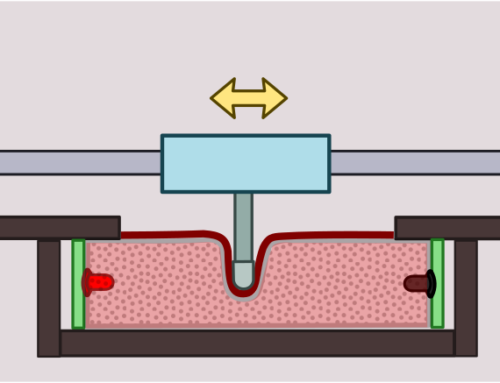

Stereolithography is a 3D printing process that uses high intensity light to selectively cure a liquid precursor into a solid polymer. Historically, stereolithography has used a moving laser beam to cure a single spot (or voxel) of material at a time. Digital Mask Projection Stereolithography (DMP-SL) replaces the laser with a conventional digital projector. In a massively parallel process, a digital projector uses a Digital Mirror Device (DMD) to independently control more than two million pixels of light. Using a digital projector increases the speed of stereolithography by curing an entire layer at the same time.

The basic DMP-SL process is shown in the schematic to the right. First a 3D model of an object is sliced into images for each layer, with white pixels for all solid areas. Each image is projected through the transparent bottom of a vat of liquid precursor. After the layer has fully cured, the build platform is raised and the next layer is projected. This process continues until all layers have been formed. This process can be seen in the video below:

Working within the Organic Robotics Lab at Cornell University, I developed a DMP-SL system with a nominal resolution of 35 µm. Typically a layer height of 50 µm with a build time of approximately 25 mm/hr. The first printer prototype is shown above and source files can be downloaded here:

- Source: Github

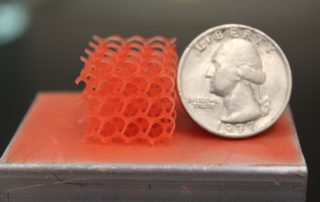

Example prints using this system are shown below. My research page includes work using this system to directly print high degree of freedom pneumatic actuators.